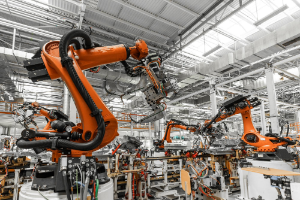

Industrial automation

We specialize in providing expert services including diagnostics, maintenance and repairs for the entire industrial automation sector.

A wide range of equipment

Our team of highly trained technicians has years of experience in repairing and maintaining a wide range of electronic equipment, including PLCs, HMIs, VFDs, and many more…

1. Programmable Logic Controllers (PLCs)

2. Human-Machine Interfaces (HMIs)

3. Servo Motors

4. Variable Frequency Drives (VFDs)

5. Industrial PCs (IPCs)

6. Industrial Ethernet Switches

7. Motor Control Centers (MCCs)

8. Circuit Breakers

9. Power Supplies

10. Sensors

11. Actuators

12. Control Valves

13. Control Panels

14. Data Loggers

15. Signal Conditioners

1. Frequency Converters

2. Temperature Controllers

3. Timers

4. Counters

5. Relays

6. Contactors

7. Pressure Transmitters

8. Flow Meters

9. Level Sensors

10. Safety Switches

11. Encoders

12. Inverters

13. Positioners

14. Power Distribution Units (PDUs)

15. Radio Frequency Identification (RFID) Systems

From manufacturing and logistics to healthcare and agriculture

A&D SERWIS stands at the forefront of device maintenance, providing comprehensive repair solutions across diverse sectors. We play a crucial role in keeping these businesses operational and efficient.

Technologies & Devices

AI is transforming the industrial automation electronics sector by enabling machines to learn and make decisions based on data analysis, improving efficiency and reducing errors.

Autonomous Mobile Robots (AMRs) used in warehouses, factories, and logistics centers for tasks such as material handling, inventory management, and order picking.

IoT technology is being used to connect devices and sensors in industrial settings, enabling real-time monitoring and control of equipment and processes.

Smart thermostats, which allow for remote temperature control and energy management in homes and buildings.

Cloud computing is providing new opportunities for industrial automation electronics by enabling remote access and management of equipment and data, improving scalability and flexibility.

Cloud-based building management systems (BMS) used to monitor and control heating, ventilation, and air conditioning (HVAC) systems in large buildings.

Big data analytics is being used to analyze large volumes of data generated by industrial automation electronics, providing insights and identifying opportunities for optimization and improvement.

Predictive maintenance systems used in manufacturing plants to monitor equipment performance and predict potential breakdowns.

Digital twins are virtual replicas of physical equipment, allowing for real-time monitoring and predictive maintenance to optimize performance and reduce downtime.

Wind turbine digital twins used to monitor and optimize wind farm performance and maintenance.

AR technology is being used to provide workers with real-time information and guidance, improving safety and efficiency in industrial settings.

AR-enabled smart glasses used by maintenance workers to access real-time data and instructions for equipment repair and maintenance.

Robotics technology is advancing rapidly, enabling the development of new applications and capabilities in industrial automation electronics, such as autonomous vehicles and drones.

Collaborative robots (cobots) used in manufacturing to work alongside human workers in tasks such as assembly and packaging.

Edge computing is being used to process and analyze data locally, reducing latency and improving response times in industrial automation electronics.

Edge devices used in industrial control systems to provide real-time data processing and decision-making capabilities.

5G technology is enabling faster and more reliable wireless communication between devices and sensors in industrial settings, improving efficiency and enabling new applications.

Autonomous vehicles, such as self-driving cars, that rely on high-speed, low-latency 5G networks for communication and navigation.